IOT-LINK – New industrial IoT gateway

IOT-LINK – Compact and very affordable industrial IoT gateway with Linux and 4G LTE

IOT-LINK is the latest ARM-based industrial IoT gateway from Compulab – and IOT-LINK now available in our product lineup.

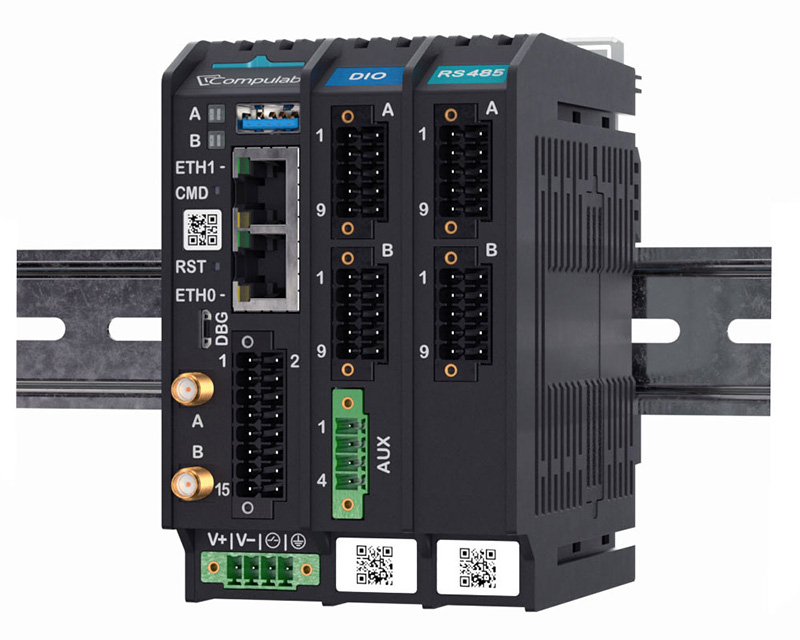

Designed with a strong focus on reliability, cybersecurity, and flexibility, IOT-LINK combines powerful hardware with a wide range of industrial-grade interfaces – all packed into an ultra-compact, fanless, and rugged enclosure. This makes it an ideal solution for modern edge computing, automation, and IoT deployments in demanding industrial environments.

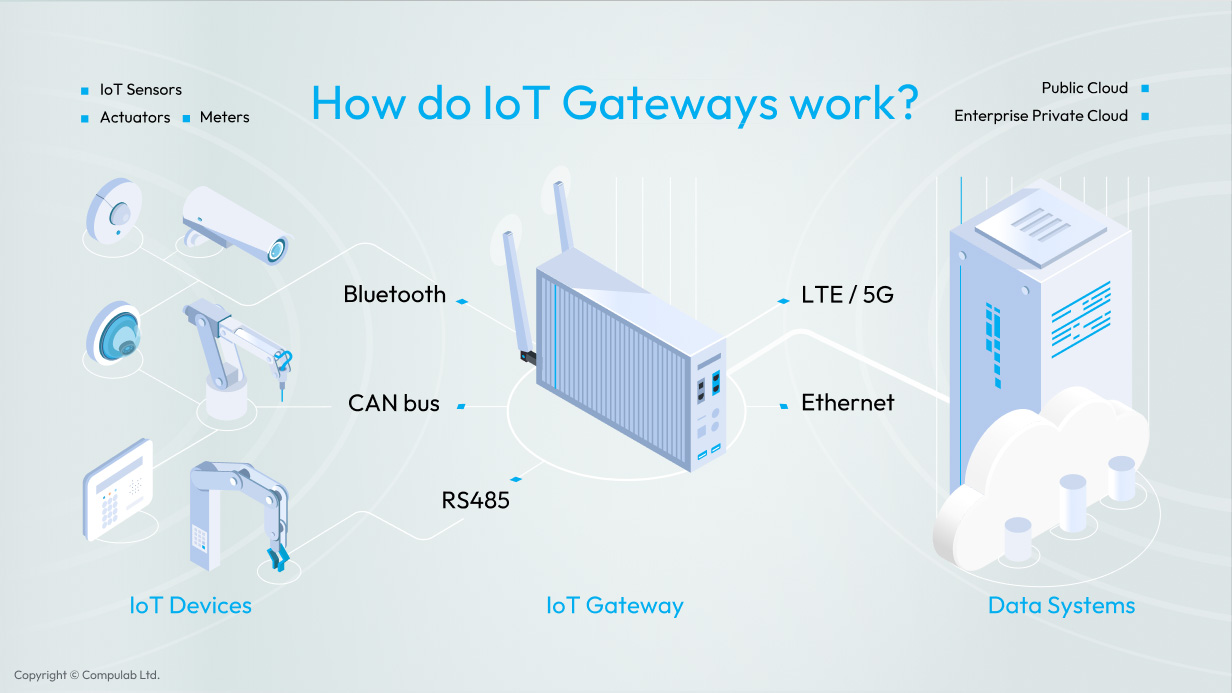

Designed for industrial IoT

IOT-LINK is built around the energy-efficient NXP i.MX93 dual-core Cortex-A55 processor, delivering an ideal balance between performance and low power consumption.

The device is engineered for operation in harsh environments, supporting a wide temperature range from -40°C to 80°C, and is compatible with both DIN-rail and wall mounting options.

Key Highlights:

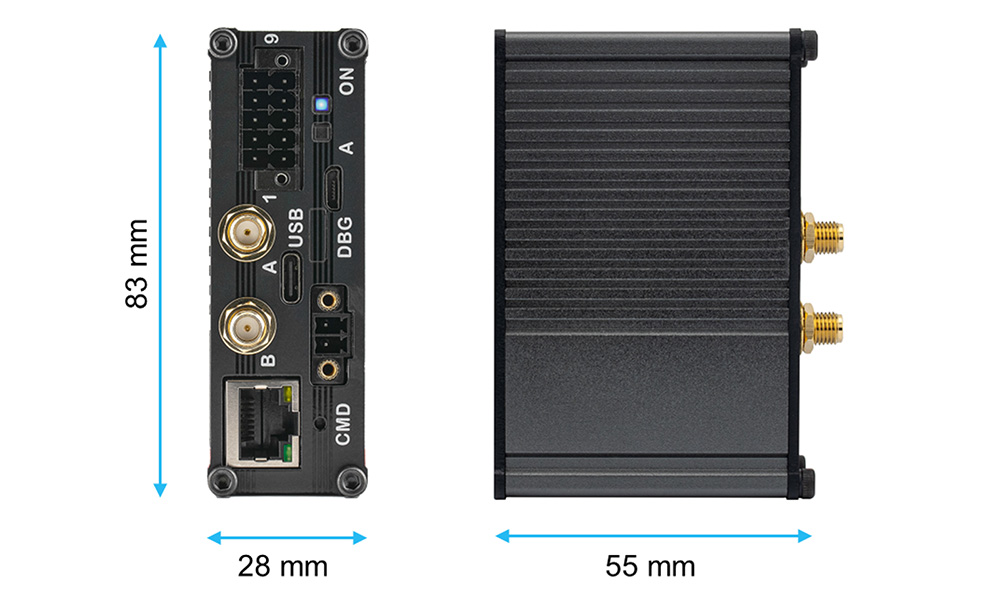

- Global 4G/LTE modem (CAT-1 bis) and Gigabit Ethernet

- Wi-Fi 6, Bluetooth 5.4, Zigbee, Thread, and Bluetooth Mesh

- 2x RS485 / CAN-FD and 3x digital inputs/outputs

- TPM 2.0, Secure Boot, and hardware watchdog

- Compact form factor: only 83 x 28 x 55 mm

Advanced Linux software – ready for Docker and OTA updates

IOT-LINK comes with Debian 12 Linux and Docker preinstalled – ready for immediate deployment in edge environments. For advanced customization, the following are also supported:

• Yocto BSP (Linux kernel 6.6, Yocto 5.0, U-Boot)

• Mender for OTA updates

• BalenaOS, supported through official collaboration with Balena – ideal for fleet management and container-based systems

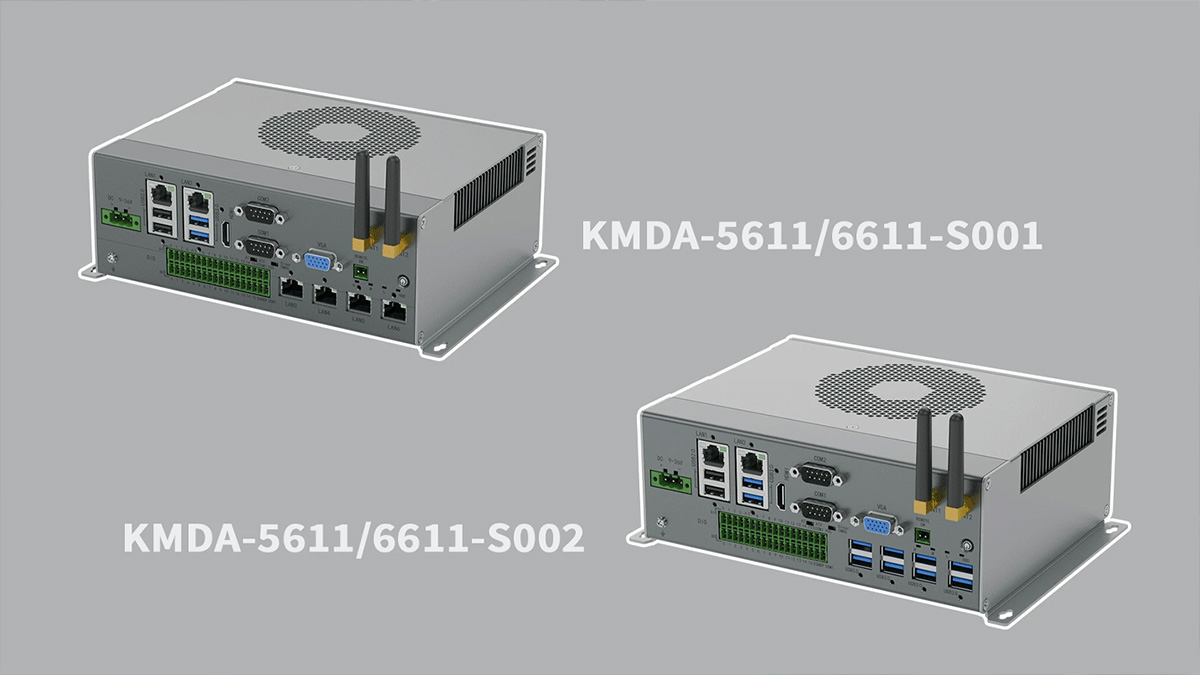

Flexible integration – also available as SBC or SoM

For integration into custom hardware solutions, IOT-LINK is also available as SBC-IOT-LINK (Single Board Computer).

Additionally, OEM partners can build complete solutions based on the MCM-iMX93 System-on-Module, enabling a smooth transition from prototype to mass production while leveraging the existing software stack.

Typical use cases:

- HVAC and building automation

- Smart energy management and battery storage

- EV charging stations and fleet management

- Lighting and traffic control in smart cities

Contact us to learn how we can support your project

As an official Compulab partner, we offer:

- Local support and technical consulting with a focus on IoT and Linux

- Pre-configuration with Debian, Yocto, or Balena

- Long-term product availability (up to 15 years)

Contact us and book a meeting:

Kevin Peter Gade

As always, our door, telephone or mail box is open, should the above give rise to questions or simply for a chat and sparring.

Send a Email

Or contact us by phone at +45 7027 0415

Sign up for our newsletter to be updated about the new products and solutions we offer.